No products in the cart.

We Have All the Sizes and Configurations You Could Ever Need for Your Custom Printed Pouches

Do you have bags for Cosmetics

?

YES!

How to Pick the Right Custom Printed Pouches

It can be a daunting task to pick the right packaging but our configuration guide makes it easy!

Our Most Popular Custom Printed Pouches Configuration — The Stand Up Pouch

These are the perfect wholesale custom printed pouches printed with YOUR logo!

These bags are outfitted with a bottom gusset, that when deployed, allows the pouch to “stand up” on the shelf in a store. Stand up pouches, commonly referred to as SUPs also have more space than a three seal bag with the same outer dimensions.

Many of customers order their custom stand up pouches with a hang hole too, in case the store or shop wants to hang them rather than stand them on a shelf. It’s always good to be versatile to help your distributors sell more of your product!

With over 40 films to choose from, we have a material that will ensure your stand up pouch is the highest quality. We can also combine materials in a custom stand up pouch. For example combining a black film with a clear film. To learn more about sizing and pricing of custom printed pouches and printed stand up pouch projects, give us a call today at 949-336-1541.

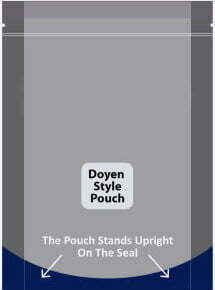

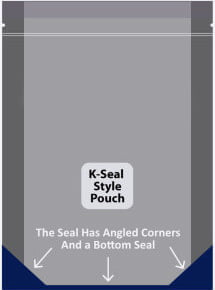

Stand Up Pouch Gusset Styles

We can help you decide which configuration is best for your product.

The Doyen is very common – the U-shaped seal at the bottom of the front and back panel. U-seal reinforces a large area of the pouch by sealing the front panel and back panel each to the bottom gusset.

The K-Seal is the intermediate style. This is characterized by a K-style seal at the corners, and a flat bottom seal across the bottom edges. Similar to the Doyen in that the bottom gusset supports the weight of the product.

As the contents get heavier, it becomes important to reduce the force on the bottom gusset. To do this, we can introduce the corner seal style. The pouch relies on the weight of the product to provide rigidity and stability.

FDA & EU Food Approved

Great Prices to Meet Your Budget

Fast + Free Shipping on All Orders

Would You Prefer a Stock Stand Up Pouch?

Check out our huge selection of stand up pouches that are in stock and ready to ship.

2 Seal Pouch – Fold Over Bottom

The best non stand up pouch solution for ESD Shielding Bags and Loose Fill Materials

2-Seal pouches have been around a very long time. Made to fold over similar to standard “Ziploc”-style pouches, the bottom of these bags can fold over from one continuous piece of material. A fold over 2-side seal pouch with its fold over bottom is less rigid configuration, allowing lose product to fill in where other types of bags prevent it.

Many customers are interested in this configuration either because it matches their current design, or they want a flexible non-stand up bottom. There’s no need to completely up-root product specifications.

While for many applications the 2-side seal pouch has been eclipsed by the stand up pouch or a 3 side seal, there are many applications where a 2-seal pouch is preferred. Most notably a 2-side seal is the basis of all ESD shielding bags.

• Tried and true design.

• Great for ESD shielding application.

• A less rigid configuration, more flexible.

• Emulates Flow Packaging, and fast Tubing.

• Easy Machine Loading.

Why Choose a 2 Seal Pouch?

The 2-seal packaging design is proven, tried and true and emulates flow packaging for simplicity and ease of use. The fast tubing and easy machine loading also allows for a more seamless production process.

Although not as popular as the 3 side seal or stand up pouch, 2 side seal bags are nevertheless highly requested by our customers because of their more flexible configuration.

More Flexible, Less Rigid Configuration

Because the 2-side seal pouch confirms to the product inside, it’s ideal for loose products, where crumbs or other debris could get stuck in the zippers of inferior pouch products.

Our two side seal pouches are FDA approved and unprinted 2 side pouches can be in your hands in as little as two weeks. Our low order quantities start at just 5,000 bags, making it easy for your customers to enjoy your products without the high overhead.

Need it Printed? No Problem!

Another key benefit of 2 side seal bags are their flexibility and readiness for printing. Not only does this help you save on the labor costs of applying labels to each of your pouches, but it also makes the end product much more attractive to customers.

And whether you choose a printed or un-printed version, you’ll be glad to know that our convenient 2 side seal pouch bags are compatible with over 40 different barrier materials, so you can add even greater protection to your product by mixing and matching the right type of barrier to prevent moisture, oxygen and other types of contamination as well as preventing electrostatic discharge both inside and outside of the product packaging.

Get a Custom Two Side Seal Pouch Quote Today!

Because we have numerous options to choose from when customizing your two side seal pouch design, it can feel overwhelming deciding what you need — but you don’t have to do it all alone!

Our packaging professionals can work with you to determine the best materials at the best price point so that you can feel confident that your custom printed pouches are durable, protective and easy to use.

You know your product, and we know how to package it – because your product is worth it!

The 3 Side Seal Pouch

The best solution when you don’t need your bag to sit on a shelf – great for products like frozen foods, candies, jerky, cannabis, pharmaceuticals and more!

With lower price points than Stand Up Pouches pouches, the 3 Side Seal Pouches are widely used because of their ability to be easily and quickly filled with product. In the 3 side seal configuration, you load your product in the same way that customers remove it, through the top. Additionally bags with zipper could be used without heat-sealing (but it’s not recommended).

If you think about it, a 3-side seal flat pouch could be the perfect packaging for your product. Easy and quick, load the 3 side seal pouch through the top, seal and done! Your product will stay fresh and moisture and oxygen free until your customer opens the packaging.

If you are in need of these little unsung heroes,

give us a call at 949-336-1541.

Tamper Evident Pouches

The preferred FDA pouch configuration because food crumbs and debris cannot get caught in the zipper during filling.

Tamper evident pouches are widely used because of their ability to be easily and quickly filled with product. In a tamper evident configuration, the top of the pouch (above the zipper) is pre-sealed during the pouch creation. The bottom of the bag is left open. This allows you to fill the pouch without having to contend with the zipper, or worry about inaccurate heat seal placement. A more professional look because the top seal where your customer looks is sealed during creation.

FDA & EU Food Approved

Great Prices to Meet Your Budget

Fast + Free Shipping on All Orders

Looking for a Tamper Evident Stock Pouch?

Check out our huge selection of tamper evident pouches that are in stock and ready to ship.

Square Bottom / Side Gusset Pouch

The square bottom bag is an older pouch configuration that is often used in the coffee industry and many others.

Before the invention of K-style or Doyen Stand Up Pouches, the only game around was Square Bottoms. Square bottom pouches are a older configuration of pouch, still popular with the coffee industry, and many others.

• Square Bottom Pouch can be used with most closure options

• Fully Printable (front, back, sides, bottom)

• Best for thicker materials

• Not compatible with spouts.

As the bottom gusset provides the stability and allows the pouch to stay upright, the proper choice of which style to use is important. Typically, there are 3 options:

• Doyen (also called Round Bottom or Doypack)

• K-Seal

• Corner Bottom (also called Plow (Plough) Bottom or Folded Bottom)

The Custom Liquid Spout Pouch

The liquid spout pouch configuration is specifically designed for liquid fill applications from juice, to baby food.

This configuration is gaining popularity due to the cost savings of spout pouches over other liquid packaging, such as jars or rigid plastics.

Spout for loading / and end user.

• Gusseted bottom allows the pouch to stand up on shelves.

• Compatible with Digital, and plate printing

• Spout can be either side mounted or top mounted.

• Spouts can be combined with die-cuts.

Filling and Loading Spout Pouches

Spout pouches are primarily designed for FDA applications, and can be made of Hot fill compatible materials for sterilization. Hand funnel loading, and auto machine loading can both be used. For small scale production, a open side heat seal zone can be added to the configuration to aid in pouch filling.

Applications & Markets for the Spouted Stand Up Pouch

We can customize the Liquid Spout Pouch to your customer specifications with a choice of sizes and colors.

Packaging Bag Features

BPA Free

Cost effectiveness

Re-closable spout

Non-breakage

Non-leakage

Personalized closure, no risk of ‘glass inside glass’.

Spout Pouch – Key Features

Excellent for liquid packaging.

Rounded corners

Easy open tear nicks

Tamper Evident ring

Ideal for consumers on the go.

Spout pouches can be self standing for great on-the-shelf appeal.

Spout Pouch Application

Liquids

Food Ingredients

Baby Food / Beverages

Jam & Honey

Personal Care

Soups / Sauces

Dairy Products / Pet Food

Diecut Shaped Pouches

The diecut shaped pouch offers the ultimate flexibility with your pouch design, from circles to shapes, the die cut custom configuration allows for maximum customization.

Why choose the Diecut Shaped Pouch?

• Diecut almost any silhouette

• Compatiable with pour spouts

• Stand Up Pouch or Lay Flat configurations

• Fully printable.

Common Applications For Shaped Pouches:

• Drink Pouches

• Baby Food

• Marathon energy Gels

• Syrups

Ordering Shaped Pouches

• Minimum order is 5,000 pouches

• Digital and Plate printing available.

• Optionally setup as Spout Pouches.

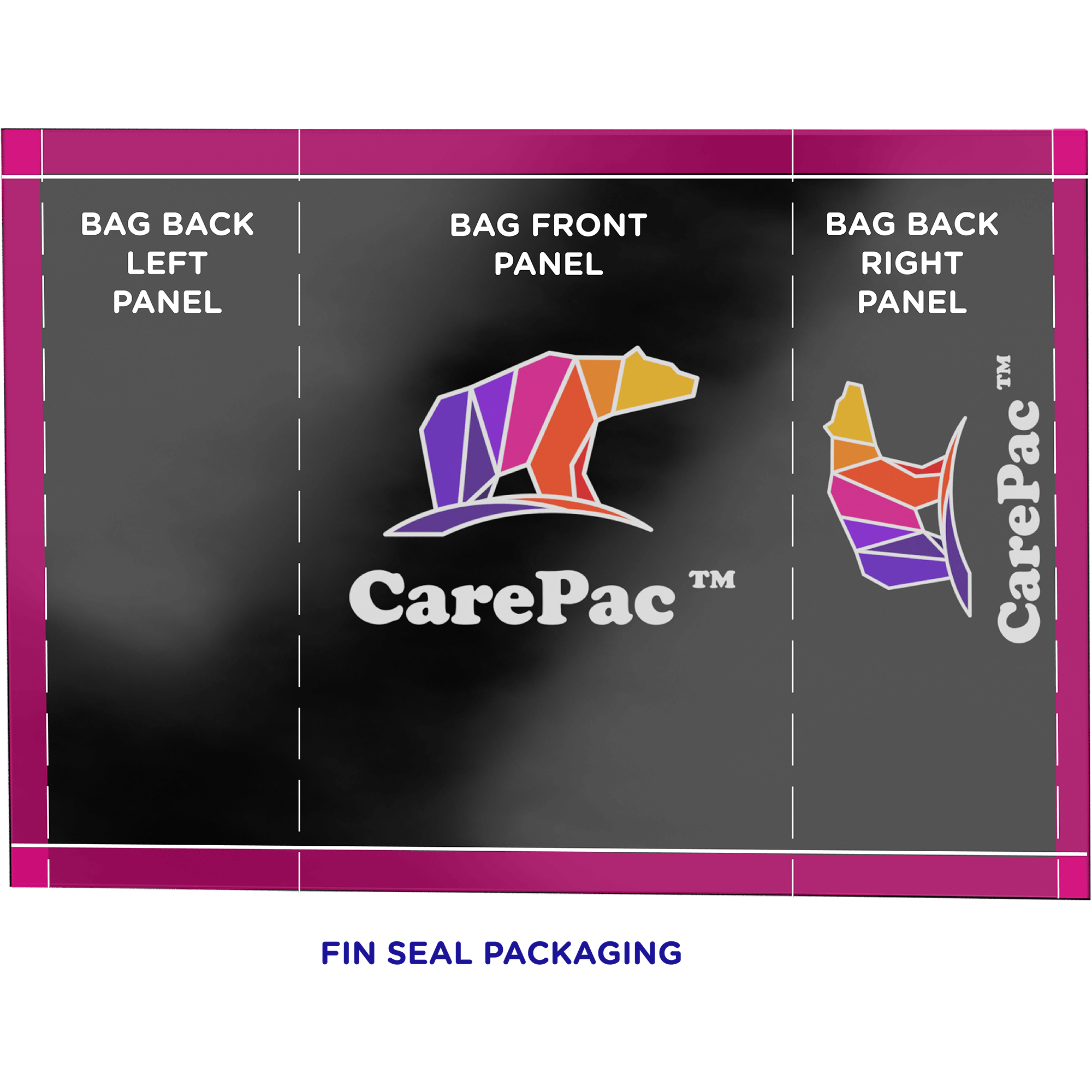

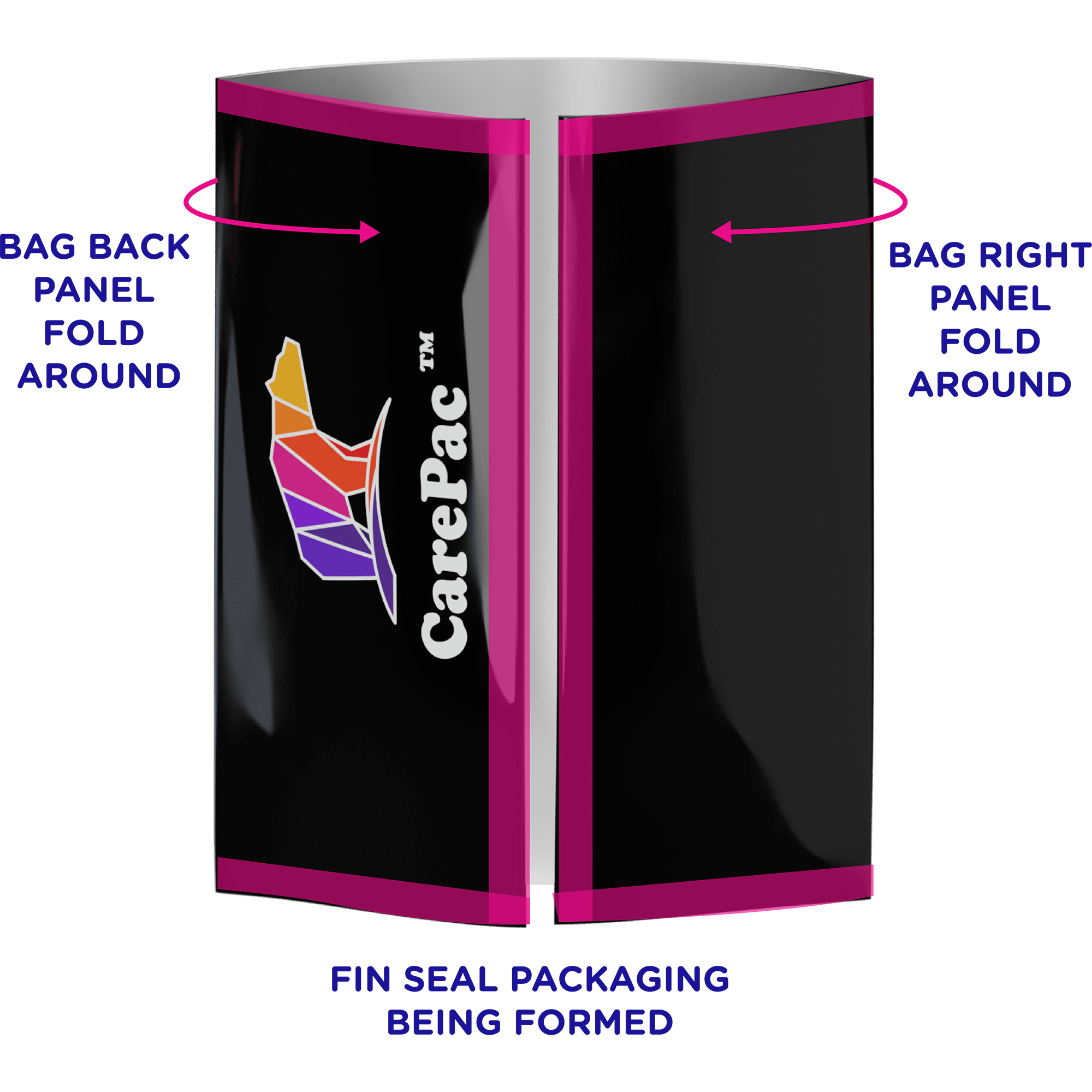

Fin Seal Pouches

Fin Seal Pouches are a form fill design and are used in certain fill machines.

Fin Seal Pouches are available both as a finished pouch and a fin seal tubing ready configuration. Fin Seal pouches are a traditional pouch design that has been used successfully for years. Predominately associated with high speed and automatic filling environments. We sell both Fin seal ready roll stock, and fin seal bags.

• High speed loading configuration.

• Compatible with Inno-Lok zippers.

• Available in Fin and Lap Configurations.

• Back Right / Front / Back Left layouts.

• Printing

Fin Seal Pouches Configuration

Fin seal bags come in many different shapes for a wide variety of uses. This bag has been used for many different type of products such as candies, gummy, instant noodles, and frozen dumplings. Common in the supermarket shelves is the packing Lay’s or chips as well as colorful gummy and candy grain.

Three-Side Seal Fin Seal Bag

Three-Side Seal packs with fin shaped seal can be effectively opened by getting the back seal, so they have for some time been utilized as bags for things like snacks. These fin seal pouches can likewise be hung in stores with hook holes included the seal area.

Side Gusseted Bag

Fin seal gusset bags are often used for things like coffee. Their main feature is that they can obtain a nice cube shape by vacuum filling.

Fin Seal Quad Seal Bag

Unlike conventional Shark-fin bags, Quad Seal bags make it conceivable to include a wide range of significant worth according to your needs. These are the main sort of Shark-blade pack that zippers can be added to. Triple Zip and Easy Lock can be utilized with this pack.

Fin Seal Pouches | Customized Print

Fin Seal Pouch is the simplest pouch with a back and bottom seal.

In addition to consumer retail goods, fin seal pouches is widely used to aid in the distribution of printed promotional materials and product samples. Like baseball cards, flat stock coupons and business premiums are encased using fin seal overwrapping. The packets are then glued to magazines, newspapers and other periodicals to be efficiently distributed to circular subscribers. Furthermore, they can be printed customisation of logo, design, and information with an attractive visual appearance.

Whether you need printed or unprinted Fin Seal Pouches, we can supply fin seal pouches to your specific dimensions. Wrap your product in clear or beautifully printed flow wrapping film. It can be made with fin seal on one side or lap seal, also called it Center Seal pouch or T-seal pouch, Pillow Pouch, Lay-flat Pouches. The Fin seal pouch is normally used for packing potato chips and fried snack foods.

Fin Seal Packaging

Fin Seal Packaging Being Formed

Final Fin Seal Packaging

Get a Custom Fin Seal Pouches Quote Today!

Because we have numerous options to choose from when customizing your fin seal pouches design, it can feel overwhelming deciding what you need — but you don’t have to do it all alone! Our packaging professionals can work with you to determine the best materials at the best price point so that you can feel confident that the end result is durable, protective and easy to use. You know your product, and we know how to package it – because your product is worth it!

Flexible Barrier Tubing

Flexible barrier tubing can also be configured to work in a FFS style for most FFS machines

Choose any of our 40 stock flexible barrier materials and we will create continuous flexible barrier tubing of any width from 1″ wide to 36″. Dualweb designs are also available so, for example, you can create at tube of black or white material on one side, and clear on the other.

• Economical

• Flexible quantities and roll lengths.

• Dual-Web (dual material) setups.

• Select any stock film or we can develop a custom structure.

Why Choose Custom Printed Pouches?

Demand for your product is growing, and so is your business. But you:

Can’t find the right packaging size.

Yep, standard bags often don’t fit.

Are you exhausted from hand labeling?

No more! Please help me! – Yep we can pre-print. One pouch doesn’t fit all. We know. That’s why we’ve tailored solutions to help you get the pouch that’s right for your product.

Wonder why your competitors packaging looks so professional?

Don’t make your product fit the packaging, make your packaging fit the product.

Custom size 3-side seal flat pouches

You choose, we deliver. We will produce custom size bags with any features, size or materials you choose.

Custom printed flat pouches

Stand out from the crowd. We print any branding elements on the base material of your choice and produce your bags with it.

Stock 3-side seal pouches and bags

No branding? No problem. We will ship you stock sized bags right away, no customization required.

Frequently Asked Questions About Custom Printed Pouches

Q: What’s the minimum order quantity for custom printed pouches?

Testing out a product? Not sure if branding is right yet? No worries, you can make a small order (as low as 5,000 flat pouches).

Q: What kind of material can I use for my custom printed pouches?

Choose from a huge selection of materials, over 50 barrier materials to build your bags from.

Q: Are your custom printed pouches certified?

Yes, including FDA, BPA free, TSE free, Kosher, RoHS and REACH certified. Wow!

Q: What if I have questions about custom printed pouches?

Need assistance with technical art setup or just have questions? Whether your business is big or small, our staff is more than ready to help you.

Q: What are you lead times? How soon can I get my custom printed pouches?

Tired of waiting forever? No more! Your order could be ready within 2 weeks on non-printed bags or 4 weeks on printed pouches. Now, that’s quick!

Experience and Quality You Can Trust

At CarePac, we have over 5 years of experience packaging liquids including fruit juice, water, baby food, oil, salad dressing, and even alcohol and wine. Our pouches can be filled hot or cold, and can be refrigerated, frozen, or kept at room temperature. Each pouch is designed based on the product’s specific needs: how it will be filled, shipped, stored, and ultimately sold on a retail store shelf.

For custom printed spouted pouches, our minimum run starts at 5,000 pieces. Spouted stand up pouches can be printed in up to 40 colors, and the spouts and caps can be applied in your choice of location, on the top center, in either corner, or in special positions like the sides. In addition, with CarePac, you’re always guaranteed top quality and value.

The Custom Printed Pouches Supplied You Can Build Your Business On Experience and Quality You Can Trust

Are you looking for a custom stand-up pouch supplier who will give you superior quality, outstanding customer service and highly-competitive pricing?

CarePac is a family-owned, California-based manufacturer of commercial-grade FDA approved custom stand-up pouches. We do everything in-house, start-to-finish. If it CAN be made, we can make it here...to your exact specifications, every time.